Special Production

Raw Material

First of all, it is made into flat coil wire by rolling iron as raw material in iron and steel factories.

It is generally produced at 9.5 mm or over in international standards.

Afterwards, it is rolled again to be brought to the desired size according to the sectors; then it is distributed to production areas.

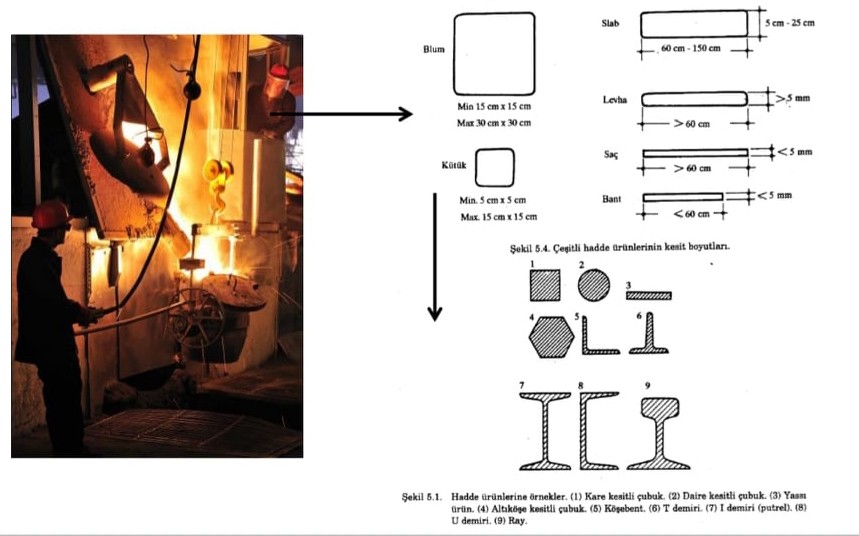

Rolling

Ingots are obtained by filling the liquid metal into cast iron permanent blocks and leaving it to solidify, and blooms, slabs and billets are obtained as the first product by hot rolling the ingots. Products such as profiles, rails, bars, sheets and pipes are obtained By re-rolling bloom, slabs and billets.

The Rolling Process is basically divided into two as hot rolling and cold rolling.

Hot Rolling:

Hot Rolling:

Initially, the transformation of ingots into blooms, slabs and billets is usually done by hot rolling.

Cold Rolling:

Cold Rolling:

Quality surface and precise dimensional control play a major role in the production of sheets, tapes and foils with enhanced mechanical properties.

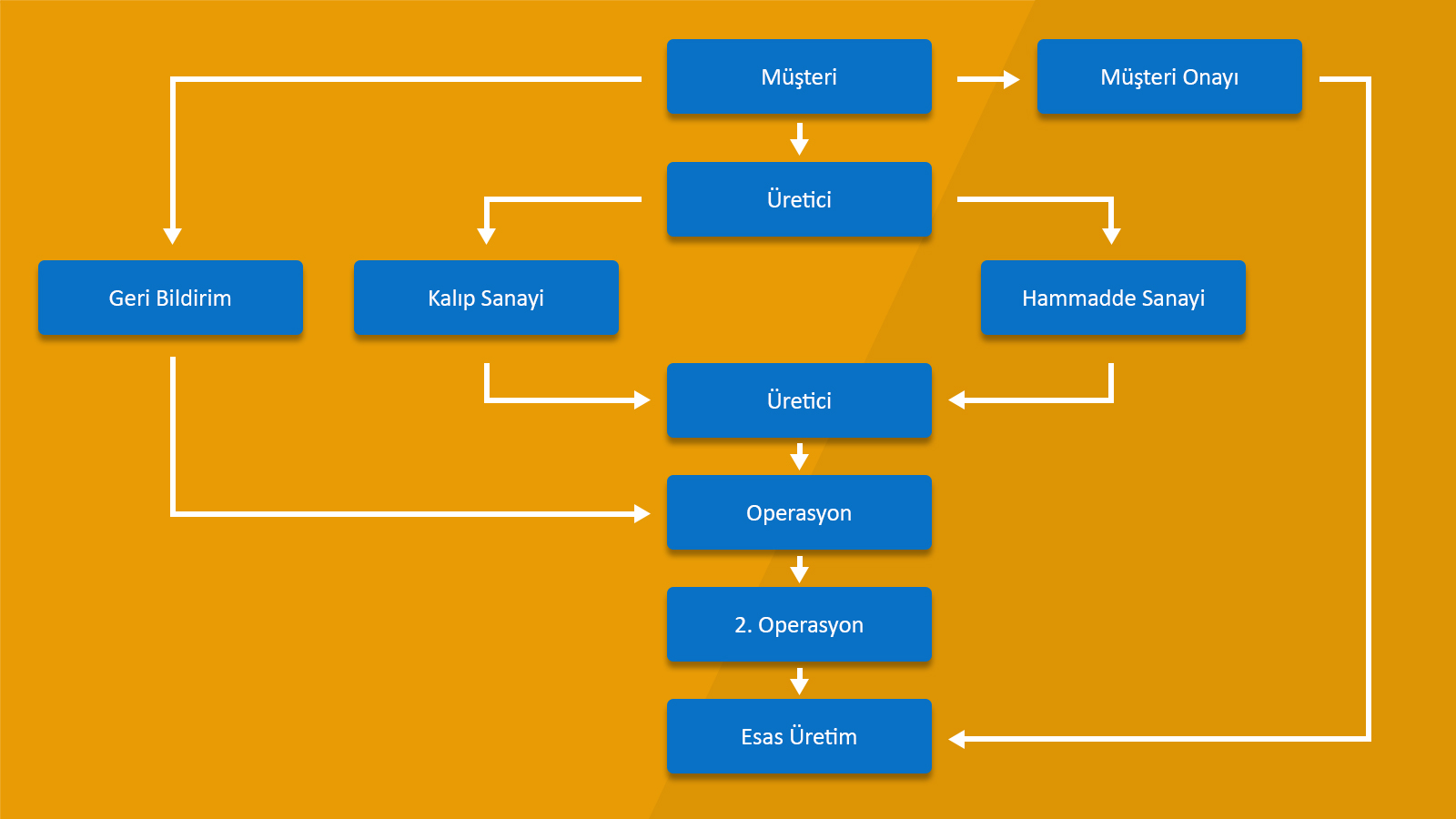

Production Stages

Production stages follow between Raw Material > Mold > Press.

The raw material to be used before production is determined As rivets with or without heat treatment, depending on where they will be used.

Finally; The surface coating (color) is determined according to the place where it will be used, and the products that come out of the production are shipped to the customer after the coating and packaging processes.

Production Site

Videos