OUR VISION

To be a preferred solution partner by providing safe and ethical services as promised, by inspiring through creating innovative design, generates value by growing.

SPECIAL FORM

SPECIAL FORM

-

Special Production

We offer solutions for the products that our customers need with our various standard and specially designed rivets and screws.

-

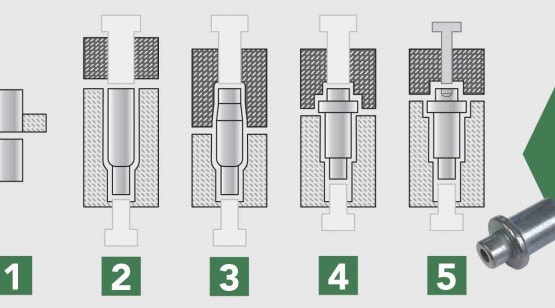

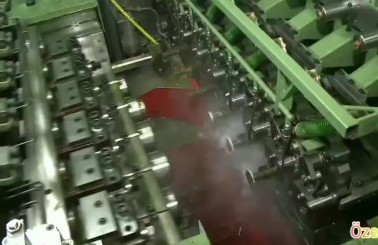

Cold Forming

The first reason why cold forming production is preferred is that it can be produced at more affordable costs compared to other technologies.

-

Special Products

We offer inspiring innovative solutions for all your needs with the production of special rivets and screws in the desired size and form.

International StandardsSpecific ProductsCustomer Rights

Use of materials in accordance with international standards and norms.

We offer solutions for the products that our customers need with our various standard and specially designed rivets and screws.

Special designs to meet the needs of every sector.

We offer inspiring innovative solutions for all your needs with the production of special rivets and screws in the desired size and form.

Commitment to customer rights is essential.

We make production safely, paying attention to ethical values and as promised.

We aim to be your preferred solution partner that inspires by creating innovative designs, creates value by growing.

Iron Rivets

Iron Rivets are one of the most preferred fasteners due to their low cost. They are general joining elements that can address many sectors.

Aluminum Rivets

Aluminum rivets are more commonly used in areas that do not require load, which we call light production, with their easy formability. Its area of usage is increasing day by day Thanks to the hardenability of aluminum, which has been developed with the increasing technology today.

Brass Rivets

It is used in production areas that do not require rust (such as faucets) where human health is at the forefront. They are rivets that can be produced in a wide variety of shapes.

Copper Rivets

Copper rivets are commonly used coupling elements in electrical and electronic productions where thermal conductivity resistance is required. It has metal grate withthe highest value in production. It is a joining element that can be used by adding various designs and printing applications thanks to its easy shaping feature.

Copper rivets are commonly used coupling elements in electrical and electronic productions where thermal conductivity resistance is required. It has metal grate withthe highest value in production. It is a joining element that can be used by adding various designs and printing applications thanks to its easy shaping feature.Stainless Rivets

Stainless rivets are an indispensable joining element in production areas where human health is at the forefront and where corrosion resistance against water is required, especially in the production of durable consumer goods. it is in the class of the most expensive and most difficult to process metals when it is evaluated in terms of market value and production.

Stainless rivets are an indispensable joining element in production areas where human health is at the forefront and where corrosion resistance against water is required, especially in the production of durable consumer goods. it is in the class of the most expensive and most difficult to process metals when it is evaluated in terms of market value and production.Silver Rivets

Silver Rivet is generally used in electrical contacts, it is a connecting element that provides high resistance to electric current, which acts as a movable contact or electrical - contact circuit breaker.

Steel Rivets

Usually steel rivets are connecting elements used in production processes that require load and certain abrasion resistance is required. They can be produced in the desired hardness according to the place used. The production stage, the type of production to be used, machinery and equipment may vary according to demand.

Graded Rivets

Graded rivets are generally used in single and double opening systems and wheel components, with mechanisms where two different parts are mounted together and one part is desired to be movable.

Graded rivets are generally used in single and double opening systems and wheel components, with mechanisms where two different parts are mounted together and one part is desired to be movable.Perforated Rivets

Perforated rivets are the products that are preferred because of the quicker and easier assembly of the products to be produced, and sometimes used as sockets.

Perforated rivets are the products that are preferred because of the quicker and easier assembly of the products to be produced, and sometimes used as sockets.Drilling Rivets

It is used in productions where mass production, easy assembly and low cost are desired. It saves you from additional operations such as the use of drills. Thanks to its easy assembly, you save on additional products such as the cost of screws and nuts used Thanks to its drilling feature.

Split Rivets

Split rivets, a type of piercing rivet also known as forked rivets, have unique designs, with split stems or pairs of legs at the smaller ends. The best uses for split rivets are soft materials such as plastic, wood or leather.

Plastic Rivets

Usage areas of Plastic Rivets is that they are produced to obtain high-strength connections in plastic, wood and many other materials.

How to Produce Screw?

They are the fasteners that are formed as a result of threading by shaping the rivet at the desired angle and degree in the rolling machine as the second production stage of the rivet, which is generally produced as a result of molding the metals in cylindrical presses.

Screw Design

It can be produced according to the desired metal in a wide variety of designs and forms with technology.

Screw Usage Areas

They are generally used in construction elements where disassembly and assembly processes are common.

Screw Material

Screws can be produced from a wide variety of materials, especially Copper, Brass, Aluminum, Steel, Stainless, Iron.

Screw Types

The most commonly used types are metric and Whitworth screws.

SPECIAL PRODUCTION

Raw MaterialProduction Stages

First of all, it is made into flat coil wire by rolling iron as raw material in iron and steel factories.

It is generally produced at 9.5 mm or over in international standards.

Afterwards, it is rolled again to be brought to the desired size according to the sectors; then it is distributed to production areas.

Production stages follow between Raw Material > Mold > Press.

The raw material to be used before production is determined As rivets with or without heat treatment, depending on where they will be used.

Finally; The surface coating (color) is determined according to the place where it will be used, and the products that come out of the production are shipped to the customer after the coating and packaging processes.